How Worn Brake Rotors Can Quietly Compromise Your Safety

Brake rotors rarely fail dramatically. Slow wear might impair stopping confidence when you need it most. Because brake pads have short replacement intervals, many drivers monitor them. Smooth braking, reliable heat control, and continuous pad contact make rotors important. Rotor wear or warping makes the braking system work harder and exacerbates minor issues quickly.

Partsavenue.ca advises rotor inspection before pad replacement. Drivers often replace brake pads without examining rotor heat stress, surface scoring, or thickness loss. After changing parts, some wonder why the steering wheel rattles or the brakes squeal. A beautiful rotor might run thin, glaze over, or wear unevenly, decreasing efficiency and increasing stopping distance. You can resurface, replace, or match pads and rotors after measuring brake feel and wear.

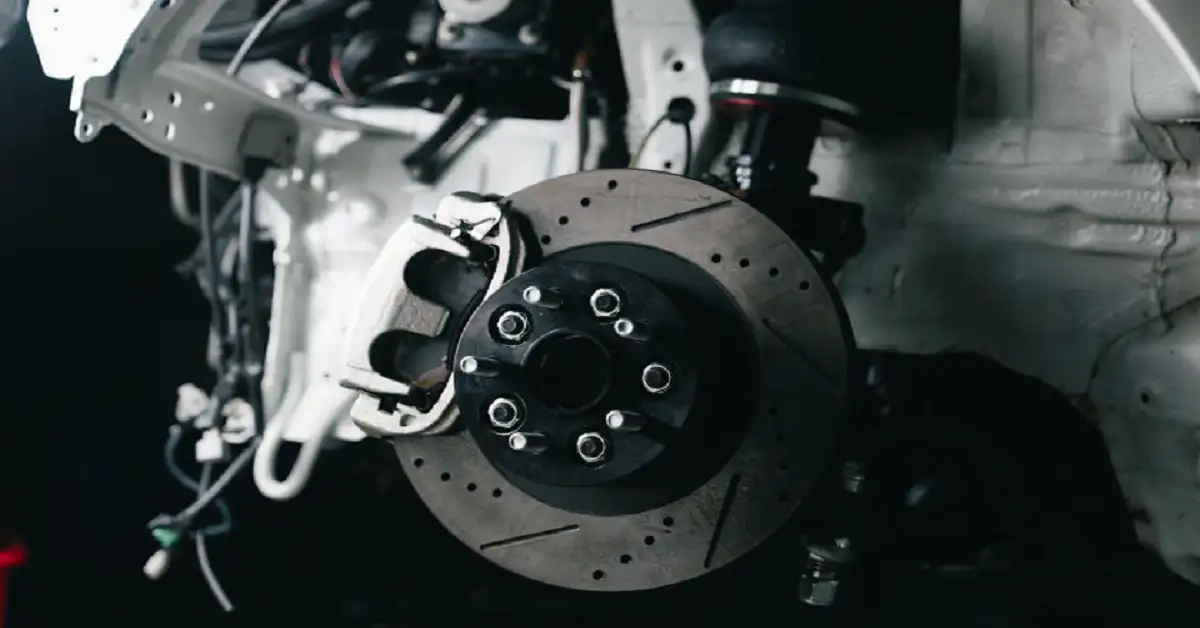

Rotors Do What?

Brake pads make contact with the rotor every time. Wheels slow and heat up from friction. Rotors can resist repeated heating and cooling, but not forever. Loss of material, grooves, and hot spots affects surface hardness. That may make ceasing less effective. Rotors affect car stability upon stopping. Powerful rotors balance pad pressure. An uneven rotor prevents pad contact. Noise, shaking, and irregular braking can result.

Rotor problems often start as minor inconveniences that drivers overlook. Minor brake pedal shaking is a frequent symptom. Many find the buzzing slowing down. Braking with a trembling steering wheel is another sign. The front axle rotors may be damaged. Noise might also deceive. Worn pads, glass, or uneven rotor surfaces can cause screeches. A prolonged grinding sound may indicate worn backing plate pads, which could quickly damage the rotor. Even infrequent touch can cause uneven wear, so monitor noise.

How Rotors Wear and Why It Matters

Rotor wear exceeds thickness. Surface matters as much as depth. Deep grooves reduce the pad contact area, causing stops to occur farther apart and generating hot spots. Heat from rapid braking or frequent stops can weaken wheels. The pad may twist and move unevenly. Running out is another matter. The rotor wobbles. Dirt between the rotor and hub or unequal lug nut torque might cause runout. Wear and tear may contribute. Shaking, uneven pad wear, and erratic stopping are common.

Wet or Emergency Stops: Unknown Safety Risk

Worn brakes are dangerous in emergencies. Wet circumstances necessitate consistent bite and smooth modulation. The pad may not hold consistently if your rotor is damaged or uneven, diminishing your confidence in stopping quickly. Emergency-stopping rotors must be able to withstand high heat immediately. Heat and wear can cause rotors to fade, vibrate, and wear more quickly.

Anti-lock braking systems (ABS) and stability control only work in newer cars with excellent mechanical brakes. If the rotor condition causes inconsistent friction, those methods may function, but the stop may not. Good technology can’t fix bad hardware.

Smart Brake Service Process

Good brake maintenance begins with inspection. Measure rotor width and check grooves, hot areas, pads, callipers, and hardware. Clean the hub, torque the wheels, and let them settle to match friction surfaces before installing new pads and rotors. Brake rotors don’t always screech when unsafe. They gradually diminish until you need maximum stopping force. A comprehensive service program can effectively monitor rotor wear to ensure road safety.